APEX Technology

Discover the science behind one of ADAR’s innovative waste transformation technologies

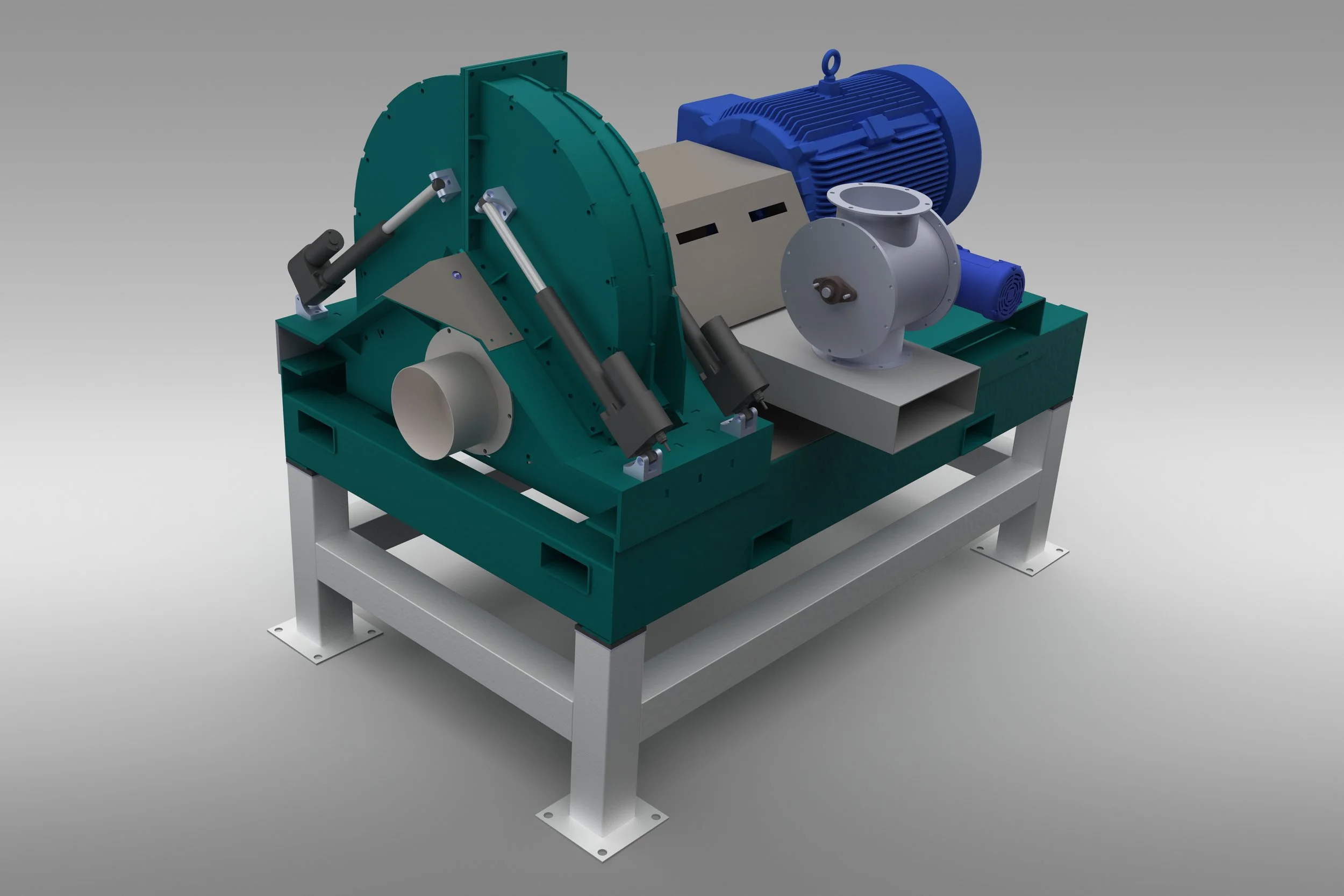

APEX™ Industrial Processing System

High-throughput material transformation—engineered for demanding industrial feedstock

APEX™ is ADAR’s next-generation system designed for operators who need industrial-scale throughput, consistent output quality, and flexible integration into existing operations.

Turn hard-to-handle material into stable, shippable value

APEX is built to help you:

Reduce moisture and stabilize feedstock

Create a consistent, powderized output

Improve handling, storage, and transport economics

Enable downstream reuse, resale, or safe disposal pathways

Output: a dry, stable powder engineered for your target specification (particle size, moisture range, handling characteristics).

We combine the power of our ADAR Shockwaves with the effectiveness of our industrial milling technology!

The ADAR principle—applied at industrial scale

ADAR’s platform is based on a physical principle you already use to explain ADS: when a jet breaks the sound barrier it creates a sonic boom—ADAR reverses that idea and applies high-frequency acoustic shockwaves to the feedstock.

In APEX, those shockwaves are engineered for industrial duty cycles and throughput, enabling rapid processing without relying on:

Added heat

Fossil fuels

Harmful chemicals

The result: fast, efficient processing designed for high uptime and real-world plant constraints.

Avocado pits before processing

Dried, pulverized, and sanitized avocado pits shown after processing

Built for operators—not scientists

APEX is designed to be straightforward to run: clear operating modes, simple start/stop logic, and an intuitive interface—so teams spend time on outcomes, not complexity.

Designed for:

Quick onboarding and repeatable operation

Remote support / diagnostics (if enabled)

Predictable output consistency across batches

The end product? A valuable powder with a range of commercial applications:

Livestock feed: Affordable and sustainable.

Biofertilizers: Supporting regenerative agriculture.

Green energy solutions: Accelerating the renewable revolution.

Why operators choose APEX

Lower total processing cost

Reduce handling and transport inefficiencies by stabilizing material closer to the source.

Operational flexibility

Designed to integrate into existing material flows (infeed/outfeed, conveyors, containment, dust control, etc.).

Better downstream options

A consistent output opens options: reuse, resale, blending, pelletizing, co-processing, or controlled disposal pathways.

Platform advantage

APEX isn’t just equipment—it’s a scalable system that can evolve with your feedstocks, specs, and facilities.

USE CASES ARE ENDLESS - From Industrial Waste to Food Byproducts!

We configure APEX to your throughput and footprint!

APEX can be deployed as:

Pilot / demo system (prove performance, validate output markets)

On-site production system (continuous, integrated into plant operations)

Multi-unit scale-out (increase throughput by adding modules)

Smarter Technology, Smarter Decisions

At ADAR, we're constantly pushing the limits of what's possible today. Our Acoustic Dehydration Solution (ADS) isn't just about hardware—it's about harnessing data to empower our customers to be more productive, sustainable, and profitable.

We sell solutions, not just equipment. By combining cutting-edge technology with advanced data analytics, we're revolutionizing sustainable material processing. Our software enhances our capabilities, allowing us to monitor crucial metrics and provide actionable insights.

Through the power of data, we're transforming the way industries manage materials, waste, and resources. Whether in food processing, waste remediation, or resource recovery, ADAR is dedicated to delivering comprehensive, data-driven solutions that drive efficiency and sustainability.

Frequently Asked Questions

-

APEX is designed for industrial feedstocks. Share your material profile (moisture %, contamination, target output spec) and we’ll advise fit.

-

Unlike conventional dryers that rely on sustained high heat and fossil fuel inputs, APEX utilizes ADAR’s acoustic-based processing principle. This can significantly reduce energy intensity, eliminate combustion-related permitting complexity, and lower operating costs depending on the feedstock and configuration.

-

APEX is designed to integrate into existing material flows with minimal disruption. Standard integration typically includes infeed conveyance, power connection, and output handling. Custom automation and dust containment options are available depending on your plant layout.

-

Operating cost depends on throughput, moisture reduction targets, and local energy pricing. During the qualification process, ADAR provides a modeled cost-per-ton analysis based on your specific material profile and projected runtime.

-

APEX is engineered for repeatability. Output consistency is influenced by inlet material variability, but system controls and monitoring help maintain stable moisture levels and particle characteristics within target specifications.

-

APEX is designed for industrial uptime. Routine maintenance typically includes inspection of acoustic components, wear parts, and standard mechanical systems. ADAR provides preventive maintenance schedules and remote diagnostic support options.

Ready to Revolutionize Your Waste Management?

Take the Next Step Toward a Cleaner, More Efficient Future

Patent Disclaimer

ADAR’s technology is patented in the United States, Mexico, Canada, Australia, and the European Union. Additional worldwide patent applications are pending.

For questions or further information, please contact Legal@adartech.com..